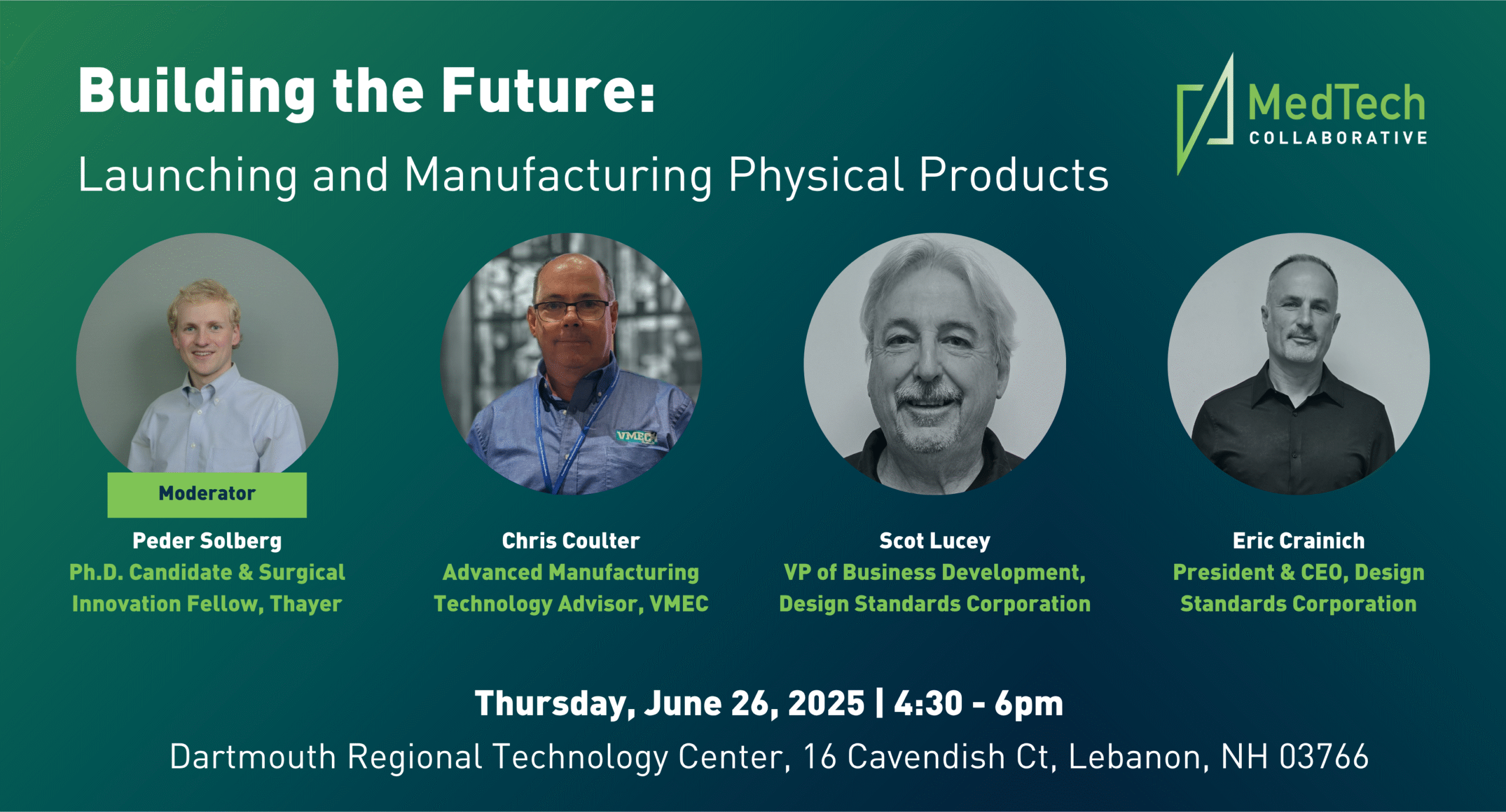

Building the Future: Launching and Manufacturing Physical Products

Thursday, June 26 @ 4:30pm

➤ Dartmouth Regional Technology Center, 16 Cavendish Ct, Lebanon, NH 03766

Bringing a physical product to life requires more than just a great idea—it demands a deep understanding of design, prototyping, manufacturing, and market strategy. Building the Future: Launching and Manufacturing Physical Products is a dynamic event designed for innovators, entrepreneurs, and product teams who are ready to take their concepts from prototype to production. Join industry experts as they share insights on navigating the challenges of manufacturing, scaling operations, sourcing materials, and ensuring quality control. Whether you're launching your first product or expanding an existing line, this event offers the tools, strategies, and connections to help you build what’s next.

Speakers

Peder Solberg

Ph.D. Candidate & Surgical Innovation Fellow, Thayer

Peder recently completed his PhD at the Thayer School of Engineering at Dartmouth, where he studied the effects of processing conditions and additives on the behavior of polymer composites for orthopedic applications. Peder was a student in the PhD Innovation program at Dartmouth, and previously completed internships related to medical device manufacturing and design at 3M, Mayo Clinic, and Total Joint Orthopedics. Peder will be heading to Medtronic at the end of July to work on heart valve technologies as a Senior R&D Engineer.

Chris Coulter

Advanced Manufacturing Technology Advisor, VMEC

A problem solver by nature, Chris has been helping product development and manufacturing companies overcome challenges throughout his career. He has been instrumental in developing new products and implementing manufacturing technology as well as working in regulated industries including defense, medical device and FDA. Chris has collaborated with engineers and businesses on a portfolio of products including medical devices, RF Connectors and electro-mechanical scientific instruments. He’s worked to improve manufacturing processes through Lean practices, methodical problem solving techniques and implementing creative equipment solutions to improve throughput and increase capacity.

With an affinity for advancing entrepreneurial ventures, Chris has worked in multiple start-up companies. In 2002 he started his own consulting business focused on assisting Vermont-based product development and manufacturing companies. He is proficient in all aspects of the product lifecycle – from market research and customer discovery to design, manufacturing, market launch and process improvement.

Originally from Massachusetts, Chris earned a mechanical engineering degree at Worcester Polytechnic Institute. When not solving problems for local manufacturers, Chris can be found mountain biking, skiing, or exploring the outdoors.

Eric Crainich

President & CEO, Design Standards Corporation

Eric Crainich is the President and CEO of Design Standards Corporation, a family-owned company founded in 1971. As the second-generation owner-operator, Eric has helped guide DSC’s growth and adaptability within the evolving medical device landscape. After earning his Bachelor of Science in Business Management and Marketing from Northeastern University in Boston, he began his career with USSC Deutschland GmbH, where he managed operations related to the manufacturing of ophthalmic and cardiovascular micro needles.

Since starting Design Standards Corporation in 1994, Eric has been deeply involved in nearly every facet of the business—including sales, operations, and project management—bringing a pragmatic, hands-on approach to leadership and innovation.

Scot Lucey

VP of Business Development, Design Standards Corporation

With nearly four decades in the medical device industry, Scot Lucey brings a deep, hands-on perspective to the evolution of surgical technology. After earning his Bachelor of Science in Biology from St. John Fisher College in Rochester, NY, he began his career in 1987 at United States Surgical Corporation, focusing on quality control for mechanical reusable instrumentation and stapling. In 1989, he joined Design Standards Corporation, where he built a broad foundation across production manufacturing, R&D, quality, regulatory affairs, sales, customer service, program management, and project proposals.

Scot has witnessed and contributed to the industry’s transformation—from open reusable instruments to the rise of single-use devices, the shift to minimally invasive laparoscopic procedures, and the advent of robotic surgery. His multidisciplinary experience offers a unique lens into the past, present, and future of surgical innovation.

The MedTech Collaborative is Proudly Sponsored By:

Stay Connected:

Join our network to stay up to date with programming and events: